Welcome to kigurumi-animegao.fr

The production process regarding a Kigurumi Mask is long and need a great accuracy. Technics employed for making a mask is based on several skills such as modelization, 3D printing, sculpting, model making as well as drawing for the initial concept art. Therefore, a kig mask, most often a unique piece, can be considered as a true work of art.

Some makers offers « generics » masks, with limited options regarding customization. Other studios, much more costly, offers to their customers the possibility to fully customize their mask and entierly made-to-measure.

Depending on the maker, the production process for a mask can last from 2 to 8 months, sometimes even more based on the current demand and the waiting list !

1) Initial shapping | 2) The mold | 3) Molding | 4) Finishing stage | |||

|---|---|---|---|---|---|---|

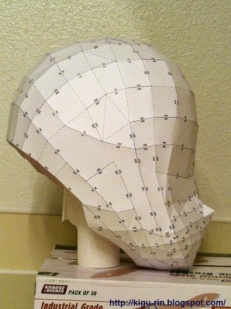

Sculpting Clay, paper pulp etc. | Folding Paper, Pepakura designer | Making silicone mold Silicone, spatula | Apply FRP *FRP : Fiber-reinforced polymers (fiberglass) | Mouth and eyes Drill, etc. | Paint Aerograph, paint, varnish | Padding Foam, cloth, glue |

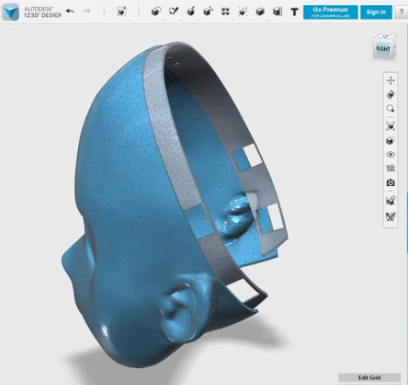

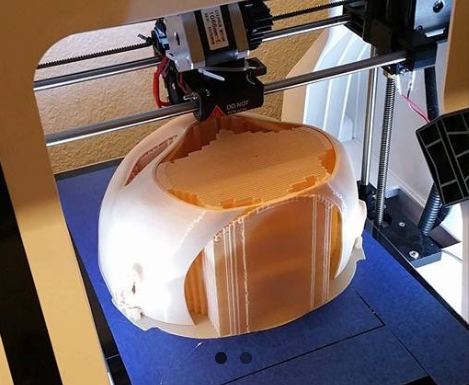

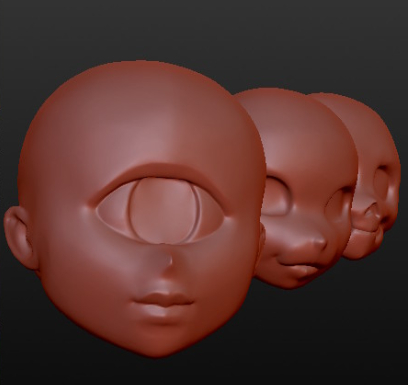

Reinforce & detail Sculptamold, Varnish, Mastic, Sand Paper, Gelcoat, Primers, etc. | Modelization 3D printer, Meshmixer, Zbrush, Blender, etc. | Counter mold making plaster bands, FRP resin, Clay, Wood | Unmolding / Glueing back Adjustment | Face Photo paper, resin, antireflective filter, net | Styling Wig, gel, Varnish, Wire, etc. | Final result |

Mask type | |||

|---|---|---|---|

Half mask Light, Cheaper, Breathable | ⅔ mask Good balance between breathability, price and mass | Full mask | Full mask |

For the most abile, it is possible to make a kig mask by yourself. The website openkig.com offers several 3D mask models for free as well as many usefull tips on production, materials, etc.